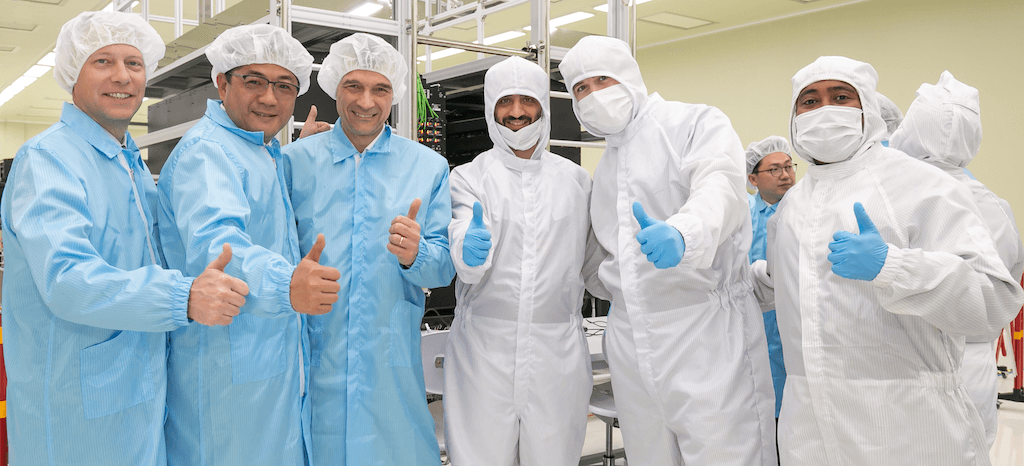

As flat panel display (FPD) technologies continue to advance, KLA unveiled its first manufacturing facility in South Korea to better serve strategic customers in the Asia-Pacific region.

The new plant in Cheonan, Chungcheongnam-do will align the production of KLA’s automated optical inspection (AOI) systems with South Korea’s premier FPD fabricators’ immediate needs for high-speed, high-precision inspection solutions that enhance yield and reduce waste.

FPD technologies like OLED and microLED are continuing to advance as the industry pursues greater display performance and versatility as well as slimmer designs and improved power consumption. As these innovations evolve, KLA is meeting new challenges for yield optimization in display manufacturing by expanding its investment in South Korea and bringing production of FPD process control systems closer to where they are needed.

“South Korea’s expertise in advanced manufacturing has positioned its FPD leaders for continued success with a new generation of agile, high-performance displays for applications ranging from automotive to augmented reality. With the strategic expansion of manufacturing operations in South Korea, KLA has the opportunity to invest in local expertise and resources while realizing significant efficiencies in delivering solutions to our customers in the region.”

Oreste Donzella, executive vice president, electronics, packaging and components (EPC) group, KLA

KLA has been a fixture in South Korea’s FPD market for almost 30 years through its acquisition of Orbotech and has played a contributing role as the market for Korean-made displays continues to flourish.

South Korean manufacturers have become indispensable links in the supply chain for many applications of automotive and commercial displays as well as for countless consumer electronic devices that people enjoy every day — from TVs, laptops and tablets to smartphones and wearable devices.

Much more innovation is still to come for applications ranging from in-vehicle cabin displays for increasingly smarter vehicles to near-field micro displays for smart glasses and AR/VR headsets. Sleek, high-resolution visual displays will play an increasingly vital role in enhancing consumer immersion and enjoyment of these applications and many others.

Strengthened Local Presence

With hundreds of KLA’s FPD systems installed in South Korea (among thousands of systems throughout Asia), the KLA FPD systems are already integral to display manufacturing in the region.

By manufacturing KLA’s AOI solutions in South Korea, shipping time and costs for regional customers are reduced significantly. The new Cheonan manufacturing location will also help to streamline KLA’s supply chain and operational efficiency, since many of the components used in production are sourced locally in South Korea.

South Korea’s display makers have set new standards for manufacturing innovation and infrastructure, and KLA’s new Cheonan facility embodies these high standards. The plant features a state-of-the-art clean room devoted to manufacturing yield enhancement solutions for the FPD industry. Direct-link communications between the new facility and KLA’s FPD headquarters in KLA Israel give the engineers real-time connectivity and control of onsite equipment for support and maintenance.

In addition to the opening of the Cheonan manufacturing facility, KLA South Korea also opened a new LKS (Learning and Knowledge Services) Training Center in Yongin, Gyeonggi-do in March 2023, further cementing KLA’s strategic and continuous commitment to invest in South Korea.

What’s Next in Displays?

KLA’s decades-long support for the FPD industry is backed by extensive R&D investments. The company has worked with customers in South Korea and around the world to surmount numerous technological barriers over the years – and many more are still to come.

FPD manufacturers have significant yield challenges to contend with when it comes to supporting the latest technologies, such as free-form and narrow bezel displays as well as integrated sensors and cameras either inside or under the display.

Upcoming challenges are related to manufacturing OLED displays for automotive and portable computing on larger substrates. Automated optical inspection (AOI) and electrical testing are essential for process control in this domain. KLA’s latest AOI and electrical testing solutions feature new sensor technologies, optics and enhanced data processing algorithms, enabling high sensitivity for even the smallest and most complicated OLED pixel designs.

Another significant yield challenge of OLED manufacturing on larger substrates is the presence of macro defects — or mura. KLA offers simultaneous micro and macro detection techniques in both optical inspection and electrical testing to help manufacturers prevent yield loss.

MicroLED has the potential to be a superior display technology offering key performance benefits such as high brightness, increased contrast and extended lifetime. Major challenges to broad market adoption include both technology readiness and cost — where improving the yield is key to moving toward high-volume manufacturing. KLA’s comprehensive portfolio of solutions for microLED manufacturing offers a pathway to yield improvement throughout the entire process — from epitaxy wafer to final display.

The global display industry will continue to evolve with continued efforts to fine-tune existing technologies like OLED, while also working toward manufacturability for emerging innovations like microLED. The drive for impressive new capabilities will need to be balanced with other developing requirements like energy efficiency.

“KLA will continue to work closely with customers in South Korea and beyond to understand their evolving challenges and continue to develop indispensable process and process control solutions to enable efficient high-yield display manufacturing.”

Tom Bailey, general manager, flat panel display division, KLA

Follow Us